This contact position may represent many different devices, including electrical breakers, liquid valve positions, alarm conditions, and mechanical positions of devices. This is usually accomplished by using an isolated voltage or current source to sense the position of a remote contact (open or closed) at the RTU site. Most RTUs incorporate an input section or input status cards to acquire two state real-world information. RTUs may include a battery and charger circuitry to continue operation in event of AC power failure for critical applications where a station battery is not available. This may consist of AC to DC converters where operated from a station battery system. It does not have moving parts and uses extremely low power and is often solar powered.Ī form of power supply will be included for operation from the AC mains for various CPU, status wetting voltages and other interface cards. In this type of configuration it is a remote unit that collects data and performs simple control tasks. For example, it communicates via RS485 or wireless communication links in a multi-drop configuration. Since RTUs may be routinely deployed in pipeline and grid guarding systems, or in other hard-to-reach or extreme environments (for example in the Biosphere 2 project), they are required to operate under harsh conditions, and implement energy-saving measures (such as switching off IO modules when not in use). Modern RTUs typically support the IEC 61131-3 programming standard for programmable logic controllers.

#Input display master software

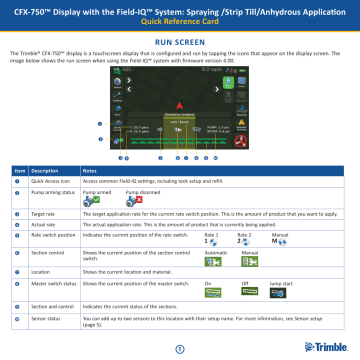

It runs setup software to connect data input streams to data output streams, define communication protocols, and troubleshoot installation problems in the field.Īn RTU may consist of one complex circuit card consisting of various sections needed to do a custom-fitted function, or may consist of many circuit cards including a CPU or processing with communications interface(s), and one or more of the following: (AI) analog input, (DI) digital (status) input, (DO/CO) digital (or control relay) output, or (AO) analog output card(s).Īn RTU might even be a small process control unit with a small database for PID, Alarming, Filtering, Trending and other functions complemented with some BASIC (programming language) tasks. An RTU monitors the field digital and analog parameters and transmits data to a SCADA Master Station.

0 kommentar(er)

0 kommentar(er)